What is a 3D Printing

3D printing is the process of transforming a 3D file from a computer program into a tangible object. The process uses additive manufacturing techniques to build the shape defined by the 3D file. Whether the design is detailed or complex, 3D printing can handle it with ease.

3D printing differs from subtractive manufacturing, which involves cutting, grinding, or drilling materials to achieve the desired shape, as seen in CNC machining.

How a 3D printing process work?

To create a 3D object, start by designing a 3D file using a computer program. There are many options available, including popular programs like Fusion 360, SketchUp, Blender, and Tinkercad that allow you accessible through web browsers such as Google Chrome or Firefox, without needing to install additional software. Save the file in a format with the extension .STL or .OBJ for 3D printing.

Once you have your 3D file, it cannot be used directly with a 3D printer. Instead, you need to convert it into a format compatible with 3D printing using a slicer program. Popular slicer programs include Cura, Netfabb Standard, and PrusaSlicer, all of which are available for free.

After configuring the settings in the slicer program, save the file in a format such as .gcode. This file type can then be used directly with a 3D printer.

What Can 3D Printing Do?

3D printing is widely used across various industries today. Some examples include:

- Consumer Products: Shoes, glasses, furniture, and children's toys.

- Industrial Products: Tools, prototypes, and various machine parts.

- Dental Products

- Prosthetics: Customized solutions for individuals with disabilities.

- Architectural Models

3D printing technology has advanced to the point where it can now create not only small items but also large structures, such as houses.

What Are the Types of 3D Printing?

There are several types of 3D printing, each classified based on the working principles of the printer. The three main types are:

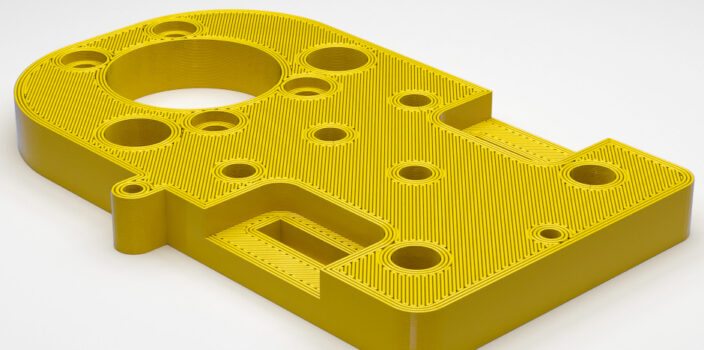

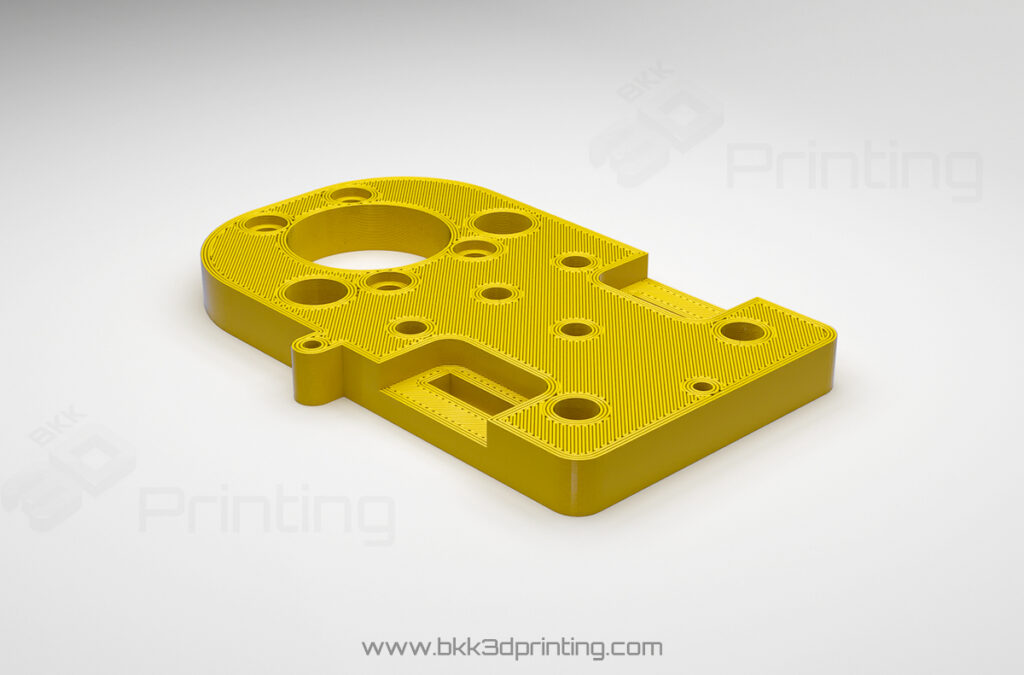

FDM (Fused Deposition Modeling) or FFF (Fused Filament Fabrication)

This popular and cost-effective method uses a plastic filament that is melted and extruded through a nozzle to build objects layer by layer.

The printer moves the nozzle or support plate to shape the material according to the 3D file.

Pros and cons of FDM 3D printing

Advantages

- Affordable printers and materials.

- A wide range of materials

- Simple to use and learn.

- Abundant resources and learning materials online.

Disadvantages:

- Limited in capturing very intricate details.

- Quality varies based on printer and material quality.

- Requires knowledge for optimal customization for good results.

Specific laser sintering (SLS) 3D printing Or SLA (Stereolithography)

SLA 3D printing, introduced in 1986, is regarded as the world's first 3D printing technology and remains highly popular today. This method offers high resolution, producing workpieces with smooth surfaces and robust resin materials. It is especially favored for applications requiring precision, such as dental products, jewelry, and various prototypes.

The working principle of SLA 3D printing involves using a UV laser to transform resin from a liquid to a solid. The printer directs the laser light to specific positions as defined by the 3D file, layer by layer, until the desired shape is achieved.

Originally, SLA printers were considered expensive and required significant knowledge and expertise. However, with advancements in technology, the cost of these printers has decreased significantly. Today, they are easier to use and produce workpieces of higher quality compared to FDM printing.

Pros and cons of SLA 3D printing

Advantages

- The finished workpiece exhibits high precision and accuracy.

- The curing of the resin in thin layers imparts high strength to the workpiece.

- The finished product is typically ready for immediate use.

- Easy to operate

Disadvantages:

- Both the printer and the materials are costly.

- Although it is easy to use, operating the printer requires knowledge of troubleshooting, as it has a relatively complex working principle.

- here are relatively few sources of information available about this type of printer.

3. SLS 3D printing (Specific laser sintering)

It is another well-established 3D printing method that is gaining popularity due to its decreasing cost. This system is ideal for producing high-resolution and durable items, such as prototypes, electronic components, and medical devices.

The working principle of this printing system is similar to that of the SLA system mentioned above. However, while SLA uses resin materials, this system utilizes polymer powder, ceramics, or glass.

The process begins with the printer spreading a thin layer of polymer powder (approximately 0.1 mm) in a heated tray, kept at a temperature below the polymer's melting point. A CO2 laser then scans the surface at specified locations, causing the polymer powder to melt and solidify. This layering process is repeated until the final shape, as defined by the 3D file, is achieved.

Pros and cons of SLS printing

Advantages

- This printing system features an integrated support mechanism, enabling it to handle very complex workpieces with ease.

- The resulting parts are highly detailed and durable.

- Additionally, it is an environmentally friendly system that complies with the EN ISO 10993-1 standard.

- The printing process is fast, and the finished workpieces are practical and ready for immediate use.

Disadvantages:

- The printers are expensive.

- It requires knowledge and expertise to operate.

In addition to the three types of 3D printing mentioned above, there are several other methods, including: Digital Light Processing (DLP): This system operates similarly to SLA but uses digital light projectors instead of UV lasers to cure the resin. Multi Jet Fusion (MJF): This method is akin to SLS but employs different material state converters. Each of these systems offers unique advantages and is suited to different applications.